Star Cool’s performance meeting unique cargo needs

In refrigerated container logistics, precise temperature and humidity control is critical. While certain perishable goods, such as bananas, grapes, and lettuce, thrive in high-humidity environments to preserve freshness, others—like onions, garlic, and pharmaceuticals—require exceptionally low humidity levels to prevent spoilage.

Precision humidity control – A competitive advantage

This was precisely the challenge faced by one of our service providers on the U.S. East Coast. Multiple customers required their cargo to be stored at a temperature setpoint of 21°C (70°F) with strict humidity control at 55% RH (relative humidity)—a difficult task in regions where ambient humidity often far exceeds these levels.

After testing various competitive units, the results were clear: alternative reefer units struggled to achieve and maintain the required conditions, barely reaching 60–65% RH. Star Cool, however, effortlessly reached and maintained the precise 55% RH setpoint, proving once again why it is the industry leader in temperature, atmosphere and dehumidification control technology.

‘’The Star Cool unit is a well-crafted refrigeration solution, built to meet the specific needs of its clients.’’

– Randy Vargas, RAVA Group Container Services

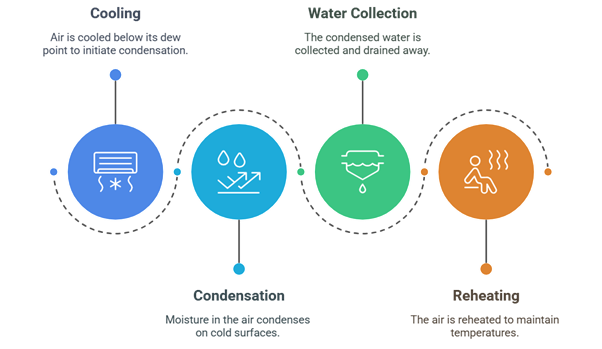

Star Cool can achieve and maintain these low RH levels through an intelligent design and operating logic, utilizing the properties of the large surface area evaporator coil, combined with digital refrigerant control valves. This allows for variable superheat control to achieve lower surface temperatures on the evaporator coil while maintaining precise supply air temperature to the cargo. Other machine designs, particularly those with fixed superheat settings, are highly limited in their ability to reach lower RH levels by cargo and ambient conditions.

Dehumidification process

With its advanced design and control logic, Star Cool can even lower relative humidity levels to 50% RH—a feat no other reefer unit can match today. One such example came from RAVA Group in Miami, Florida, where a customer storing solar panels required ultra-low humidity conditions.

Reliability when It matters most

Beyond humidity control, Star Cool also provides operational flexibility. A recent case involved a Virginia-based farm relying on four Star Cool units rented from RAVA. When one of their gensets failed, the mechanic was concerned about $350,000 worth of perishable cargo at risk. Star Cool’s service team advised him to run two fully loaded Star Cool units on a single functioning genset, something the operator had never considered possible. To his surprise, both units continued running flawlessly, saving him from additional costs and operational downtime.

These real-world experiences showcase why Star Cool remains the preferred choice for businesses that require precision, efficiency, and reliability. Whether it’s maintaining exact humidity levels for sensitive cargo or optimizing energy consumption in challenging conditions, Star Cool continues to set the industry benchmark—delivering results where others fall short.