Star Cool Integrated

Star Cool reefers will meet the needs of the most demanding customers while minimising costs.

Engineered to outperform

The Star Cool Integrated reefer effectively combines the Star Cool reefer unit and the MCI reefer box into a single unit. The result is a reefer container that makes a visible difference to the bottom line with the lowest possible Total Cost of Ownership.

Check out Star Cool selected features

StarConomy

By carefully balancing compressor and fan speed, StarConomy accurately matches air circulation to cooling demand, ensuring an ideal environment for the produce while saving energy.

Operating the fans at reduced speed once the cargo is at set point means less cooling is needed, as the motors generate far less heat while using significantly less energy compared to operation at full speed.

Dual reefer plug capability

- The standard reefer outlet is rated and

protected to 32 Amps - Star Cool’s main circuit protection is

16 Amps; that is the system max rating - 2.5mm² (~14 AWG) cable is all that is required

- Two Star Cool units can run simultaneously on a single 32 Amp outlet

- Regardless of ambient, or set temp

- No special settings, changes or software

- Dual capability on standard reefer genset

Display/User Panel

- High Definition, large size LCD

- User friendly, intuitive

- Easy access to temperature

development graphs - Logical keypad design

- Critical information on home screen

- 9 lines of data on display

Frequency converter

- This proven and reliable speed control of the compressor secures optimal match between energy consumption and cooling capacity putting cargo care as 1st priority

- Dual Compartment protects against water, moisture and dust – separated housing for print board and control/power connections

- Optimized design to protect against potential moisture, shock and extreme temperatures

Compressor

- The proven and reliable high-quality compressor is the heart of the cooling circuit

- Variable speed, 600 – 3300 rpm (20-110Hz)

- Two-stage reciprocating for increased efficiency

- Lightweight aluminum, only 58 kgs

- Maintenance-free, non-corrosive exterior made for the harsh marine environment

- Variable Compressor Speed

= Most Efficient Capacity Control

Fresh air module

- Digital setting for accuracy and safety (CMH/CFM)

- Alarm indication for open vent with frozen cargo or CA/AV operation

- Current vent position and changes to position logged to data memory

- Built in vacuum release safety

Refrigerants

Factory charged with R134a, Star Cool R513A Optimized units allow for a switch of the refrigerant at any point in time without any change of software or hardware, offering a high level of flexibility and product security as future refrigerant regulations come into force.

Engineered for reliability, the Star Cool R513A Optimized units are designed for dual compatibility with R513A or R134a without compromising capacity or longevity.

Reefer monitoring – Sekstant

An MCI purpose developed Smart Edge device including wide band 4G LTE with global coverage in a single device design, sharing battery with the reefer controller. The gateway connects the reefer container with the Sekstant Cloud and tailored OEM Sekstant user interface

Star Cool CA

Star Cool CA enables the careful monitoring and control of the amount of oxygen and carbon dioxide inside a reefer.

This means that many fresh fruit, vegetables and ornamentals can be transported further and over a longer time period, yet still arrive in fresh and pristine condition, ready for the supermarket shelves.

No thermal bridges

The removal of the dual steel and aluminum frames connecting refrigeration unit and container has minimized thermal bridges, improving overall energy efficiency.

Weight reduction

The integrated solution effectively reduces overall weight by 100 kg compared with an MCI Box with Star Cool Unit.

Weight reductions of up to 300 kg are seen when comparing to other box/unit combinations.

Outer scuff

Reefer containers are undergoing extremely rough handling and tough impacts. This may result in damages, repair and lost time in service. The scuff plate reduces risk of damage related panel delamination as well as deformation and is resistant to scratch and scuff damage that is common on chassis use.

Corrosion protection / Surface treatment

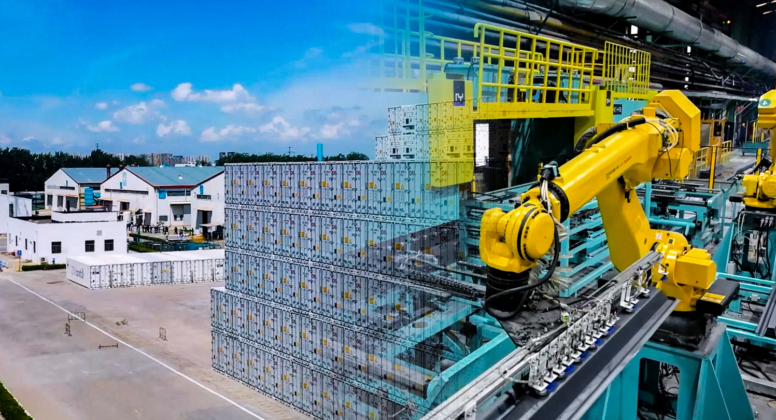

There are 20 fully automated robots spraying a uniformed layer of molten zinc metal onto all Corten steel areas. The superior effect of hot zinc metallization as corrosion protection is renowned and with automation, MCI ensures maximum efficiency and precision.

Raised base

The raised base design provides greater space between ground and subfloor that can be prone to damage from rocks, twist locks etc that could otherwise penetrate the base panels.

This M&R cost reduction design is made with flat panels between the rugged structural load members which enables simple patch repair should a puncture occur.

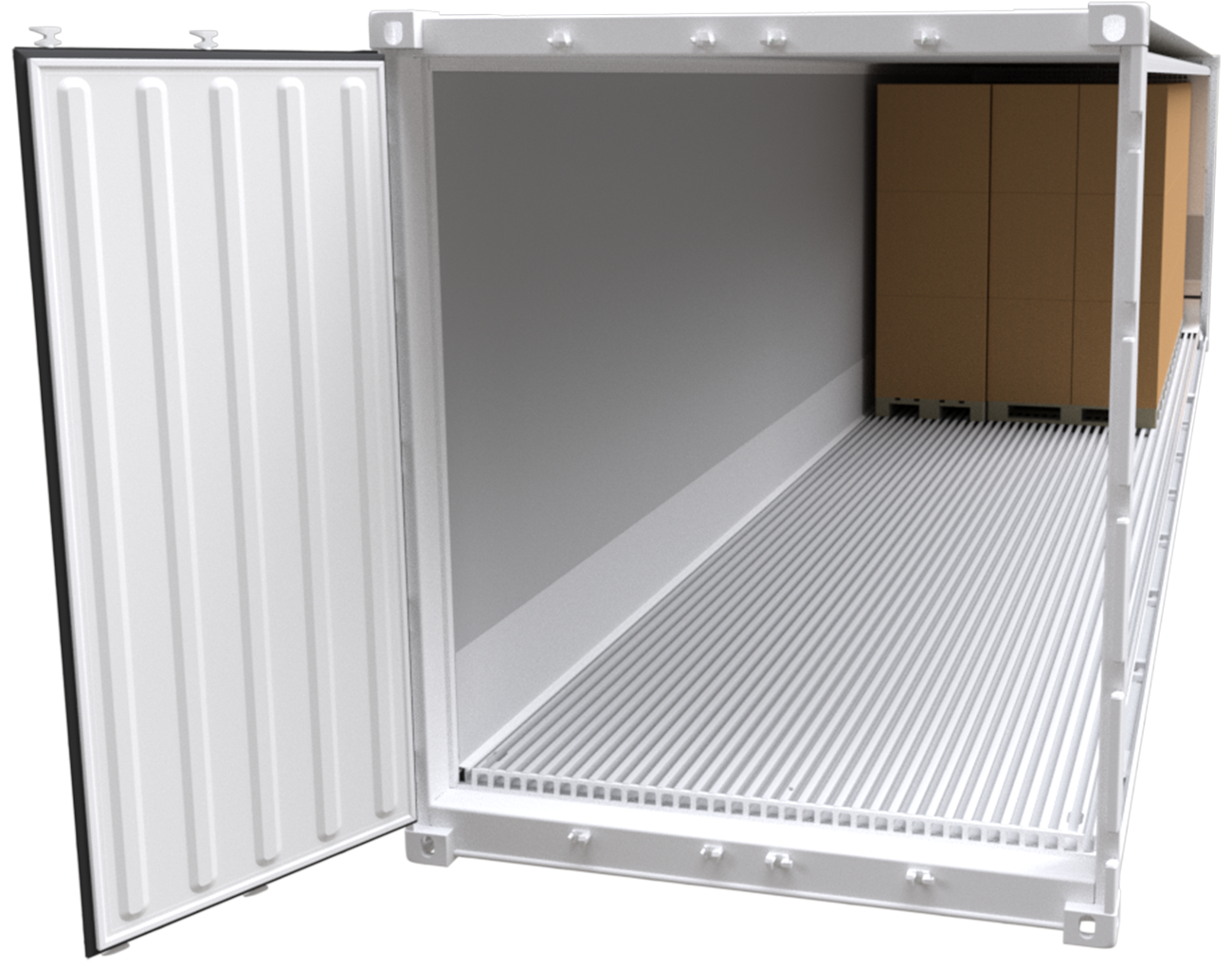

Door design

The strong doors have been designed following analysis of repair statistics and field observations. They are internally reinforced to ensure life-long operation while providing the best thermal insulation. Door moldings and gaskets are free from rivets and exposed sealant for the best sealing and hygiene characteristics.

Hot melt foam bond

Using our unique hot melt application for foam adhesion ensures 5 times stronger adhesion as well as maximum flexibility. This protects the reefer against delamination, and should a small delamination occur, it will reduce spreading of the issue.

Furthermore, hot melt application produces no VOC’s (volatile organic compounds) and is therefore better for the environment than alternative foam bond coatings.

Rear sill

Reefer containers are undergoing extremely rough handling and tough impacts during cargo loading and handling operations. This may result in damages, repair and lost time in service.

The unique box features of the Star Cool reefer ensures higher impact resistance.

Base / T-Floor

The T-floors design makes sure to facilitate air circulation required for maintaining cargo temperature while supporting the weight and loading operations of palletized and non-palletized cargo.

Refrigerants

By adjusting injection control, air flow and software for R513A compatibility, Star Cool offers an economically sound upgrade that can achieve a 56% reduction of GWP compared to the previously used R134a (GWP=1430). Among all A1 classified F-gases, R513A is the best choice to reduce the carbon footprint of reefer containers today.

Caring for cargo while saving energy

The Star Cool Integrated is designed to minimize Total Cost of Ownership. Our deep insights into the needs and requirements of the intermodal industry led to the creation of the perfect reefer unit. With low energy consumption, light weight, low M&R costs, high power factor and many standard features compared with other reefer units, Star Cool safeguards cargo while reducing operation costs and environmental impact.

Star Cool Features

Frequency Converter

Harvesting the technological development in FC’s over the last 10 years and experience gathering

Dual reefer plug

Two Star Cool units can run at the same time on a single 32 Amp outlet regardless of ambient, or set temp.

Power meter

New power meas – the online energy meter. Introduced Q1 2017.

Compressor

Variable Compressor Speed = The Ultimate Capacity Control.

Display

The display on a Star Cool reefer is user friendly, easy to access and offers visible DH LCD. This reduces risk of operational error…

Star Cool ITI

With Star Cool’s “Intelligent Trip Inspection” (ITI) the reefer conducts the same self-diagnostics as used in the normal PTI, while the reefer machine…

Star Cool Service App

Since its launch in 2018, the Star Cool Service App has proved a hit with reefer operators and shipping companies worldwide, and is designed to…

Energy efficiency

Star Cool has proven lead energy efficiency in the reefer market numerous times. This is done via detailed lab test mimicking…

Get in touch