Marking More Than One Year of Star Cool 1.1 Operation: Lessons Learned and the Road Ahead

Design, Verify, Compare

Design, testing, improvement, and iteration formed the daily rhythm at MCI’s Innovation Centre two years ago, when the Star Cool 1.1 was still being developed in the MCI Innovation Centre in Tinglev, Denmark. This process was the foundation for the development of Star Cool 1.1. Early laboratory evaluations indicated an efficiency gain of approximately 10 percent, when a Star Cool 1.0 unit and a Star Cool 1.1 unit were tested side by side in the thermal chambers in Tinglev. These controlled comparisons helped shape the expectations presented at launch.

Today, more than 60,000 Star Cool 1.1 units are in global operation, and over 10,000 of them are charged with refrigerant R1234yf. The risk assessment for using R1234yf has been independently verified by DNV, confirming that the refrigerant meets relevant safety requirements. With more than a year of real operating experience, the key question is how the unit performs outside controlled test conditions. Does it match the efficiency levels demonstrated in the laboratory, and does it align with the energy saving claims announced when the product was introduced?

Field Verification: From Manual Data Collection to Digital Insights

Historically, verifying energy performance required the installation of external power meters on selected containers and a manual upload of the collected data. The Sekstant system has changed this process entirely. Power consumption measured by built-in power meters are recorded and uploaded together with other key parameters such setpoint temperature, ambient conditions, and net frequency. This enables analysts in Tinglev to compare a dataset of tens of thousands of reefers operating worldwide with a high degree of accuracy.

The performance data confirms that the efficiency gains observed in the lab are replicated in real operating environments. Star Cool 1.1 units consistently provide stable cargo conditions and show an average power consumption of 1.6 kW per hour. This extensive dataset reduces the influence of statistical outliers and confirms Star Cool as the market’s most energy efficient reefer.

Independent Validation and Industry Benchmarking

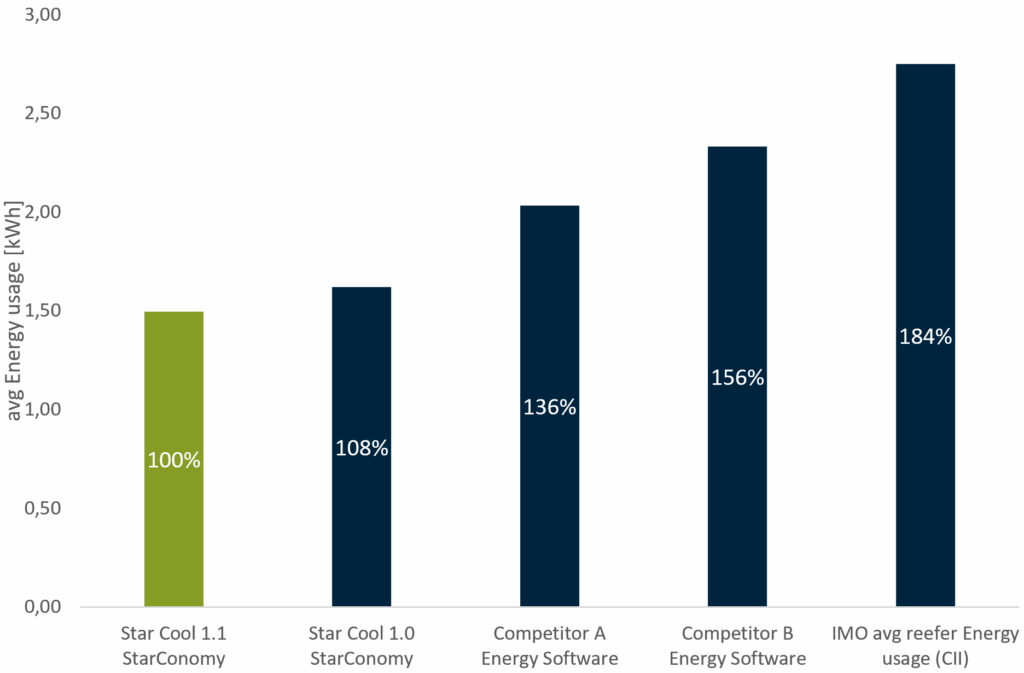

To provide further confirmation, MCI engaged Cambridge Refrigeration Technology to conduct a comparative test. Star Cool 1.1 was evaluated across several operating scenarios, ranging from rapid pull down in warm climates to part load operation in moderate conditions. These scenarios reflect the conditions experienced by global shipping lines. Competing reefer models underwent the same testing procedure, and results were averaged based on operational profiles that have previously been validated by COWI. COWI independently verified these results and confirmed the accuracy of the testing methodology and calculations in accordance with ISO 1496-2 standards.

The findings showed that Star Cool 1.1 has an average measured energy usage of 1.5 kWh. This represents a reduction of 36 percent compared to the next best alternative and close to half of the average consumption defined by the IMO’s Carbon Intensity Indicator.

Empowering Customers with Reliable Data

MCI’s focus on transparency and customer support is reflected in its benchmarking program. We have developed a customized energy consumption simulator that enables shipping lines to input their own cargo profiles and immediately see the financial and environmental consequences of different equipment selections. This tool, based on certified test data, supports customers in making informed decisions that align with their sustainability objectives.

Investing in the Future: Doubling Test Capacity

To support the growing number of Star Cool 1.0 and Star Cool 1.1 units and to continue improving reefer efficiency, MCI has expanded its testing facilities in Tinglev. The new test chambers offer improved control, a broader temperature range from minus 30 degrees Celsius to plus 65 degrees Celsius, and the ability to simulate solar radiation and other environmental factors. These systems ensure stable and consistent testing conditions and support continuous product validation and development.

More than one year into Star Cool 1.1 deployment, the insights gained highlight the importance of thorough design, field verification, and independent benchmarking. With ongoing investments in test capacity and a continued focus on customer focused innovation, MCI maintains its commitment to advancing energy efficiency and reliability in the reefer container segment.