Laser Cutting Center – Latest Automation Investment in MCI Qingdao

Continuous Progress in Manufacturing Automation

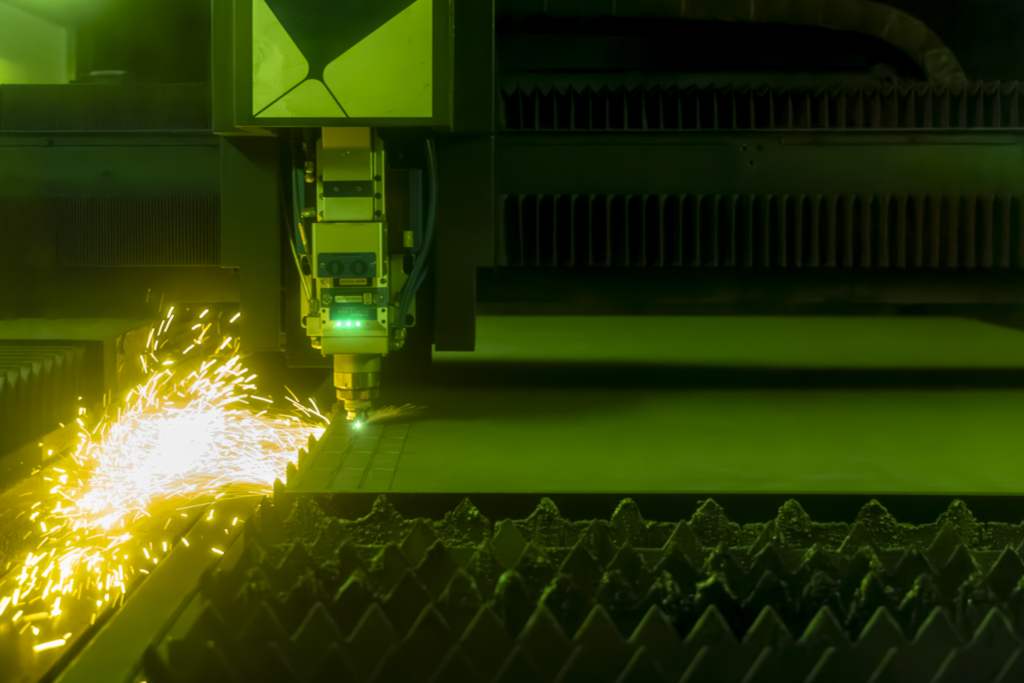

MCI’s reefer manufacturing facility in Qingdao, China, is now fully up and running with its new Laser Cutting Center. This marks an important step in the company’s ongoing strategy to upgrade and automate production. The investment reflects MCI’s commitment to improving operational efficiency, product quality, and flexibility, and it supports the company’s ambition to set high standards in the industry.

Advanced Technology for Improved Performance

The Laser Cutting Center is equipped with 10 high power laser cutting machines and 2 automated material towers. By replacing traditional shearing and punching processes, the center enables:

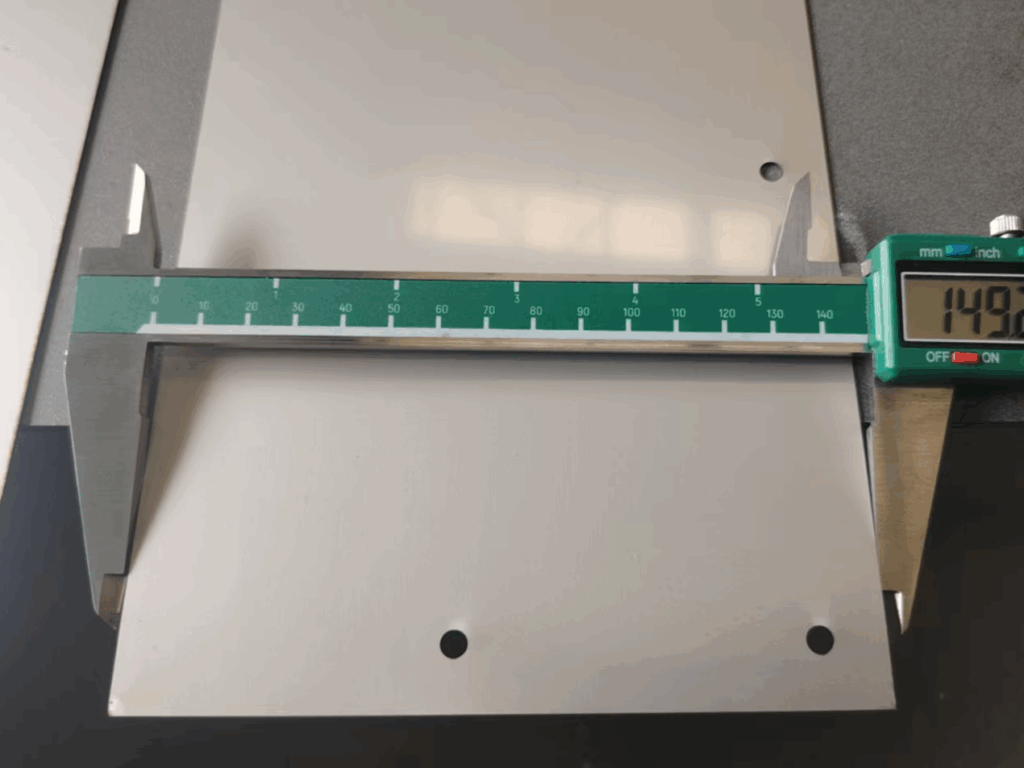

• Greater precision in plate processing, with tolerances as tight as +/- 0.03 millimeters

• Burr free edges and improved surface finish across a wide range of thicknesses

• Reduced material waste and minimized mechanical stress

• A more streamlined workflow and simplified operations

These improvements raise the quality of finished parts and support higher productivity and safer working conditions.

Smart Use of Space and Resources

The implementation of the Laser Cutting Center included repurposing existing production areas, freeing approximately 1,800 square metres in our factory line. This strategic move makes room for further automation and allows bending and welding operations to be optimized without interrupting ongoing production.

Flexibility and Future Readiness

Laser cutting technology provides significant flexibility in design because it does not require physical tooling or setup for each part. This allows for faster adaptation to new product requirements and removes the risks associated with tool wear and variation. The improved tolerances also support more consistent welding and assembly processes, reducing rework and post processing.

Commitment to Ongoing Automation

The Laser Cutting Center forms part of a broader long-term commitment by MCI to invest in automation and smart manufacturing. By creating a platform for future upgrades such as automated welding and additional process optimization, MCI ensures that its Qingdao facility remains competitive and capable of meeting changing customer requirements.