Celebrating 20 Years of Star Cool Innovation

Over the past two decades, Star Cool has developed from a concept into a trusted name in reefer technology, working continuously to advance the industry. Since the first production units left our facility in 2005, Star Cool has grown into a trusted solution for shipping lines and leasing companies worldwide driven by continuous innovation, operational excellence, and trusted partnerships.

As we mark this 20-year milestone, we look back on the journey that brought us here, shaped by groundbreaking ideas and collaboration with customers and service providers around the globe.

Scaling Up and Setting New Standards (2005–2015)

In 2005, the first production of Star Cool Units (SCUs) rolled off the line in Beijing. A vision that began on paper had become a reality.

The years that followed were marked by rapid growth and continuous innovation.

- By 2007, the demand for Star Cool had grown and production reached 10,000 units.

- In 2008, MCI opens facility in Qingdao to meet global demand.

One of the defining innovations of this era was the launch of the Star Cool Integrated (SCI) in 2007 – the first solution on the market to combine refrigeration machinery and container into a single, seamless unit. The integrated solution comes with several benefits, including lower weight, improved insulation and higher energy efficiency, simplifying operations for customers.

Around the same time, Controlled Atmosphere (CA) technology was introduced, enabling shipping lines to extend transit times for perishable goods like bananas and avocados without compromising quality.

Another key pillar of Star Cool’s success has been the establishment of a robust global service network. We recognized early on that technology requires equally strong support in the field.

One of the first partners to join this journey was Eastern (1961), a leading service provider and repair shop that has been working with Star Cool since 2007.

“We’ve worked closely with MCI since 2007, supporting Star Cool units across Asia-Pacific. As the production ramped up and technology advanced, so did our partnership,” says Mr. Hwa San of Eastern (1961). “Our teams share the same commitment to reliability and customer satisfaction, which has made this collaboration successful for nearly two decades.”

Today, Eastern (1961) and its joint venture companies employ more than 700 people across 10 countries, and continue to be recognized as reliable and forward-looking partners in the refrigerated container industry.

Driving Efficiency and Enabling Smart Operations (2015–2023)

As global shipping lines sought to improve energy efficiency and reduce operating costs, we introduced a series of innovations that placed Star Cool at the forefront of sustainable refrigerated transport.

In 2016, the launch of the control software StarConomy marked a significant step forward in reducing energy consumption. By carefully balancing compressor and fan speed, StarConomy accurately matches air circulation to cooling demand, ensuring an ideal environment for the cargo while saving energy.

Building on this, we introduced the power meter, a feature that enables operators to measure and monitor energy consumption directly from the unit. By providing shipping lines with greater transparency into reefer energy usage and documenting the associated carbon footprint from reefer logistics, the power meter supports data-driven decisions to optimize fleet efficiency.

These advances laid the foundation for Star Cool’s next evolution: digital connectivity.

In 2019, we launched the Sekstant® digital ecosystem, bringing IoT capabilities to Star Cool fleets. Powered by the Sekstant gateway, it enabled real-time monitoring, predictive diagnostics, and smarter maintenance planning, helping customers improve uptime and reduce total cost of ownership.

By 2023, Star Cool Intelligent-Trip Inspection (ITI) 2.0 was introduced, eliminating the need for the traditional labour required PTI process and dramatically reducing operational downtime.

2024–2025: A Milestone Year and a New Standard

In 2024, Star Cool reached a significant production milestone with the 500,000th unit leaving our manufacturing facility – a testament to two decades of innovation and customer trust. Star Cool had become the 2nd largest reefer brand in the world fleet.

That same year marked the launch of Star Cool 1.1, an industry-first triple-refrigerant reefer cooling machine designed to support shipping lines in meeting their decarbonization and cost targets. With the ability to operate on R134a, R513A, and R1234YF refrigerants, Star Cool 1.1 offers customers the flexibility to adopt lower-GWP solutions without compromising performance. It builds on our legacy of energy efficiency and environmental leadership, enabling operators to future-proof their fleets in line with evolving sustainability regulations.

By mid-2025, more than 25,000 Star Cool 1.1 units have already been produced, and with strong demand continuing, over 50,000 units are on order or in production – reflecting the industry’s confidence in this next-generation technology.

Looking Ahead

From the early prototypes in Denmark to a fleet of over half a million units operating worldwide, Star Cool’s journey reflects our dedication to quality, innovation, sustainability, and customer partnerships.

Today, MCI remains the only OEM designing and manufacturing both reefer machines and containers, offering complete and integrated solutions that keep cargo fresh and operations future-ready.

As Star Cool enters its third decade, the focus remains on developing reliable technologies that enable customers to operate more efficiently and sustainably – and on building the partnerships that have been vital to its success.

The Vision Takes Shape (1998–2005)

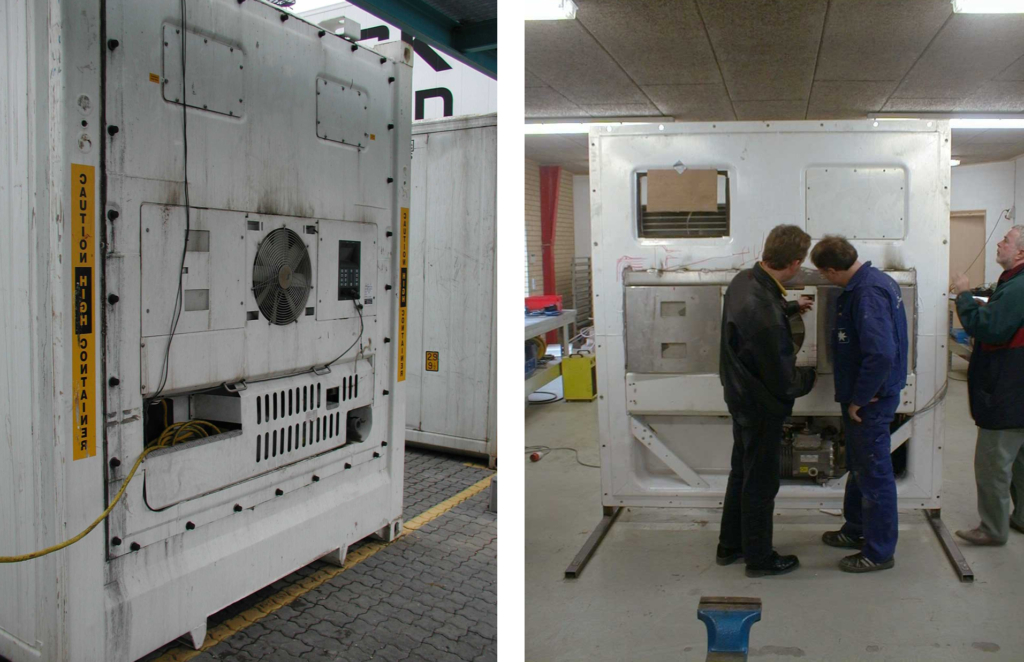

Star Cool’s origins trace back to 1998, when MCI set out to create a new reefer system that could deliver a step-change in performance. At the time, the market was dominated by a handful of established players, but MCI saw an opportunity to rethink what was possible.

In partnership with Lodam Electronics (now part of the BITZER Group), the goal was clear: design a reefer system that was lighter, more energy-efficient and cost-effective than anything else on the market.

Development was carried out in secrecy at a workshop in Ullerup, Denmark. Early prototypes were painstakingly assembled by small teams, piece by piece. By 2001, the first test units were deployed aboard Maersk vessels to transport frozen pork from Denmark to Japan. These trials proved the concept and paved the way for commercial production.