Specialist in reefer shipping, supply chain and sustainability

The last two years have been a watershed moment for practically all of us in the world. The Covid-19 pandemic, which is still lingering around the world, has transformed the way we work, and for those participating in the supply chain, created a complete new normal.

This new normal in terms of supply chain has brought about a stark reality to the refrigerated cargo world

which relates to its dependability and total interrelation with the dry cargo supply chain. Costs suddenly sky-rocketed not only on the highly visible freight rates but on all the other agricultural inputs such as fertilizers, fuel and packaging. Adding to that, cargo delays, uncertain vessel schedules and port congestion, have brought together a highly toxic cocktail of ingredients to create the perfect nightmare for shippers, traders, importers and all involved in the business of bringing fresh and healthy food to our tables from all over the world.

Dealing with these challenges has in many cases diverted attention from a much greater and important aspect of the reefer supply chain. As we emerge with stronger information tools and the understanding that our business is highly resilient, our full effort needs to focus on the concrete actions to seriously reduce carbon footprint. The moment is now as deadlines draw closer and closer and climate change will not wait, nor will the regulator.

The reefer supply chain is energy intensive; cargo must be kept at a certain temperature from packhouse/processing plant to the final consumer. Understanding, and most importantly, measuring the CO2 emissions of the long journey to the consumer, is the only real way to be able to target the reductions required. We must clearly be able to identify each segment of this journey and work with all stakeholders. We need strong incentives for each of these supply chain stake holders to actively engage in measuring the energy used to move the product and subsequently place targets on the reduction of this energy consumption in order to ultimately reduce the CO2 emissions. It is a joint responsibility.

About the Author

Philip Gray has over thirty years experience in the reefer shipping industry having started working in port operations upon graduating from Transport Engineering in his native Chile.

He emigrated to Belgium and served for a leading reefer operator in operational, commercial and management roles enabling him to gain rich experience in all aspects of the refrigerated cargo business. Since 2019 he runs his own company with focus on the Caribbean basin, and is the reefer analyst for Drewry Shipping Consultants.

MCI reducing carbon footprint

It has always been core to MCI’s strategy to support its customers’ need for highly energy efficient reefer solutions to help them meet their sustainability goals.

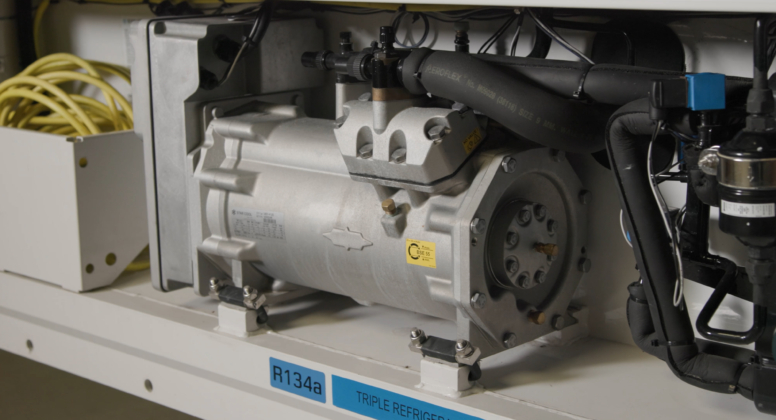

– Most energy efficient reefer with 25% gap to the best alternative

– Option to change refrigerant to R513A given a 56% GWP reduction

– Hot zinc metallization providing for the longest useful life and thereby drawing less on resources

– VOC treatment system in place since 2019

– Energy consumption/carbon footprint logged in Star Cool as standard

– The above available live in Sekstant on unit and fleet level in kWh, USD and carbon footprint metrics

Port International

The journey is long and intense as we learn from Mr. Karlsson Port, MD of Port International GmbH who launched their BEClimate bananas in 2019:

MD of Port International GmbH

How was the journey to launch BEClimate bananas?

“We recognized at an early stage that we needed to do a serious effort to reduce the carbon footprint of our produce and started working on the concept and the implementation already in 2016, so three years to supply the first box! The supply chain from farm inputs till reaching the supermarket is long and complex and we had to painstakingly identify each step from cultivation, transport, ripening and delivery to the supermarket. Most importantly the data must be legitimate and should sustain validation and scrutiny. Even the gloves used by the employees during the packing process have a footprint and needs to be calculated”.

So today for your BEClimate brand you can measure your emissions?

Most certainly, and with confidence, for example last year’s numbers show that 1 Kg of our Beclimate bananas from Peru to the consumer in the Belgian market cost 840 grams of Co2. This is one hundred percent compensated via our programs, which are direct and visible such as clean drinking water in Malawi or wind energy parks in Chile.

Measuring and compensating, how about reducing your energy use footprint?

Sustainability starts at home, our office operations are climate neutral since 2017, we have five employees from a total of 100 only working on our sustainability programs and focusing on effective reduction of effective energy use. There is much more to do, including encouraging shipping lines to be more efficient and help us in our mission of reducing energy consumption.

Subsole

For Chilean fruit export company Subsole the journey started with the implementation of solar panels, we talk to Andrea Araya who is Sustainability Manager at this leading enterprise:

Sustainability Manager at Subsole

How has your approach been towards sustainability and energy reduction?

We operate in rural areas and decided to take advantage of our sunny climate so our first step was to get as many of our farms to not only produce fruit but energy. We have six locations with solar panels and jointly we generate 2.3 million KWH per year of green energy. Much of that is used to run water pumps which is an energy intensive activity.

How do you measure your emissions at farm level?

We have now completed the first year of a pilot project. It is very complex as there are many different measuring tools, plus different end customers ask for different measurements, CO2 is only one of many Greenhouse gases.

There is no level playing field yet as to how to measure CO2 emissions from activities. Transportation is a key issue and ensuring partners are doing their utmost to improve their technology is important. Striving to deliver the most energy efficient solution throughout the supply chain is paramount as green energy will be very expensive to drive the propellers of vessels and keep generators going.

As mentioned above there is a joint responsibility, one must constantly challenge each link of the chain, at EU level the Fit for 55 Green Deal initiative (55% of emission reduction in the EU by 2030 compared to 1990 levels), is a reality. There will be a price to pay for carbon emissions. The time to act is now.